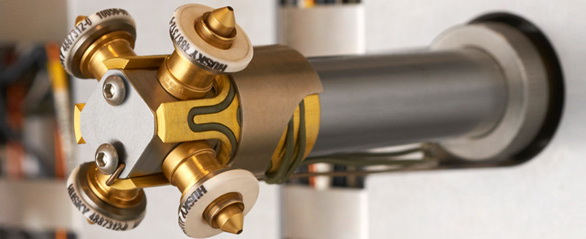

Husky Valve Gate Controller

With one of the broadest product lines in the industry husky equipment is used to manufacture a wide range of plastic products such as bottles and caps for beverages containers for food medical.

Husky valve gate controller. Ultra valve gate service manual v2 0 french. Temperature valve gate control technologies return to products page. Ultra valve gate service manual v2 0 japanese. Husky s altanium mold controllers provide the most accurate temperature integrated servo and valve gate control and the best fault recovery solutions in the industry.

Ensure that proper controls are set up to actuate the valve. Ultra valve gate service manual v2 0 spanish european. Incoe offers temperature control technology designed for optimized hot runner control performance. 1 905 951 5000.

Install the mold with a hot runner system and the valve gate in an injection press. An expert in process optimization gammaflux partners with plastics parts manufacturers to help them achieve higher quality efficiency and profitability. Husky injection molding systems is the world s largest brand name supplier of injection molding equipment and services to the plastics industry. Ultra valve gate service manual v2 1 english.

Is the world s leading supplier of temperature and sequential valve gate control systems to the plastics industry. Powered by husky s altanium mold controllers the isvg solution delivers full control of position and speed allowing profiled motion for each valve stem. The system is configured to provide the right stem force to achieve excellent gate quality. E mail global supportamericas english support toll free.

Spare parts quote request spare parts quote request. Husky valve gates come in a wide range of sizes and gating options being able to handle parts from less than 1 0 gram to parts as large as 3 0 to 5 0 kg. Proven control technology working hand in hand with our hot runner systems means you can count on consistent controllable processing with each injection cycle. 1 800 465 4875 e mail spare partsbrazil portuguese support tel.

Ideal solution for medical technical and high precision small parts. Minimum nozzle spacing of 18 mm 0 71 ultrasync e technology is compatible with ultra 350 ultra 500 and ultra 750 valve gate hot runner nozzles. 55 11 4589 7200 e mail spare partslatin america spanish support. They also feature easy to use navigation on full color screens and are available in a variety of configurations that can be implemented in any injection molding environment.

Spare parts support contact information. Additionally valve gates are often pneumatically or hydraulically actuated. The closed loop motion control provides immediate response and ensures precise and repeatable positioning. Ultra valve gate service manual v2 0 german.

Order parts click here to order.